Machine knife

Stability that convinces

Machine knives for a wide range of applications

Our machine knives stand for precise cutting performance, long service life, and maximum reliability. Whether in the wood processing, paper industry, food industry, or ice cream slicing applications – we deliver customized solutions for a wide range of industrial requirements. Manufactured from high-quality materials, our knives guarantee precise results and a long service life – even under heavy loads.

Areas of application & product variety

Veneer and rotary paring knives

These knives are specifically designed for the production of fine veneers and rotary-cut wood products. They enable even, burr-free removal even with delicate woods and ensure consistently high cutting quality. Their precise geometry and the use of wear-resistant materials make them particularly durable and enable economical operation at high cycle times. They are suitable for both manual and automated veneer machines.

Woodcutter and guillotine knives

Our wood chipper knives are designed for high impact forces and continuous loads – ideal for shredding solid wood, residual wood, and industrial waste. The robust cutting edges ensure high yields and low maintenance. Combined with our precision-manufactured guillotine knives for paper and cardboard cutting systems, we offer solutions for clean cutting edges, high dimensional accuracy, and minimal material loss – even with high volumes and continuous use.

Ice planer blade

Our ice planer blades are made of high-quality composite steel according to DIN 1.2552 and are suitable for all common ice resurfacing machines such as Dupon, Engo, Icebear, Olympia, WM-Mulser, and Zamboni. They guarantee smooth, even ice surfaces with maximum service life. They are delivered in a custom-made wooden case for safe transport and easy handling. Ideal for stadiums, ice rinks, or industrial ice-making plants.

Strip planer knife

These knives ensure precise surface finishing and consistent chip removal when planing wood. They are characterized by sharp cutting edges, high cutting accuracy, and a long service life. They deliver reliable results, especially when processing solid wood, e.g., for moldings or wood panels, and contribute to the high surface quality of the final product.

Carbide indexable inserts

Our carbide indexable inserts offer long-lasting cutting performance for a wide range of industrial applications. Thanks to reusable cutting edges, they enable efficient work with minimal tool changeover time. Whether in woodworking, mechanical engineering, or plastics processing – they are available in various geometries and, upon request, also as custom designs.

Food Processing

This section includes machine knives designed for typical processing steps in the food industry. They are compatible with all common types of equipment and are manufactured with the specific application in mind. If you require different dimensions or special configurations, we can produce them according to your specifications.

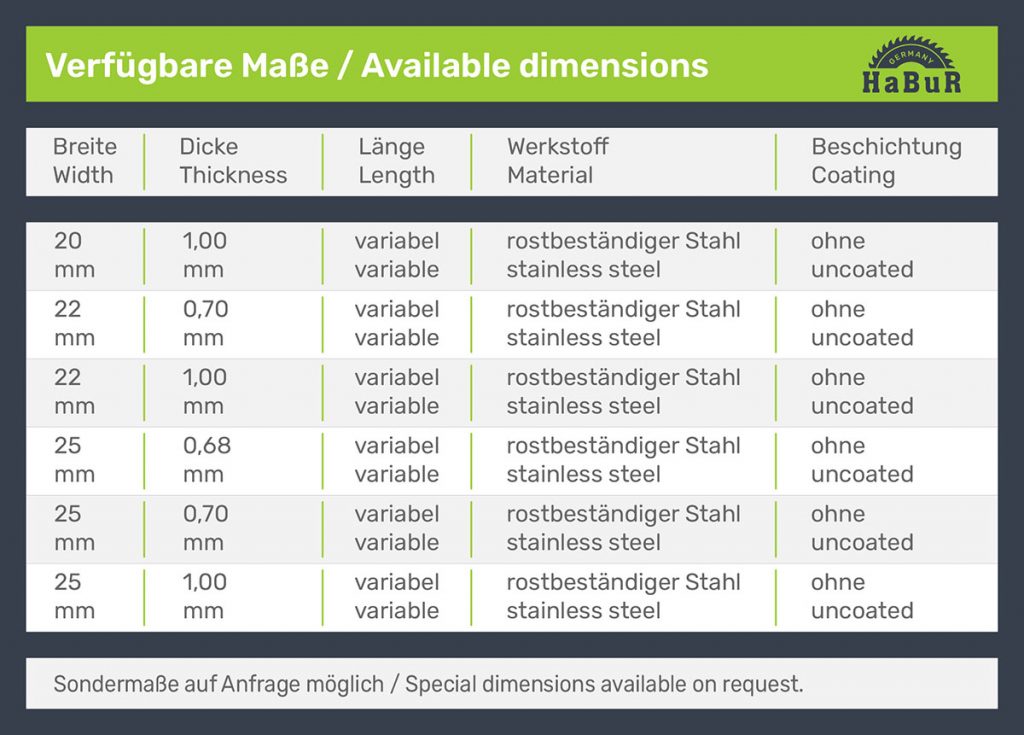

Derinding, Membrane Skinning and Fish Skinning Blades

These knives are used in the food industry for derinding, defatting and removing fish skin. They are made of corrosion-resistant stainless steel and meet high hygienic requirements even under intensive use. Their precisely ground cutting edge enables clean, controlled cuts in which skin, fat or membranes are reliably separated from the meat without damaging the tissue.

Careful heat treatment and accurate grinding processes ensure consistently high sharpness, which proves itself even during long production cycles. The knives are manufactured with tight tolerances, making them suitable for all common machine types and easy to integrate into existing systems.

The combination of material quality, dimensional accuracy and cutting precision ensures reproducible results and safe handling. Derinding and skinning knives from Habur are designed for long service life and are easy to clean. They help make processes reliable and economical, from small-scale production to industrial-scale processing.

Do you already know the dimensions you need? Then send us your inquiry and we will prepare an individual offer for you, quickly, easily and directly from the manufacturer.

Potato Blades

These specialized blades are used in the processing of potatoes. They ensure clean and uniform cuts, as required for the production of chips or French fries. The smooth cutting surface prevents damage to the product and allows it to be processed evenly.

Depending on the design, the blades are made of carbon steel or corrosion-resistant stainless steel. Both materials are durable, can be ground precisely and maintain their sharpness even under high loads. The low thickness facilitates the cut and reduces the force required during the process.

Each blade is manufactured with precision to ensure a secure fit in the holders and reliable performance. Special dimensions are available on request if production lines require a different size.

Technical Data:

Material: Carbon steel or corrosion-resistant steel

Length: 106,5 mm

Width: 18,9 mm

Thickness: 0,38 mm

Cuttin geometry: Single-edge, double bevel ground lapped

Technical Data:

Material: Carbon steel

Legth: 132 mm

Width: 18,9 mm

Thickness: 0,38 mm

Cutting geometry: Single-edge, double bevel ground and lapped

Do you already know the dimensions you need for your system? Then send us your inquiry and we will prepare an individual offer for you – quickly and easily.

Knives for Confectionery Production

Machine knives for confectionery production are used for cutting and portioning sugar masses and candy materials. They are integrated into various stages of the processing line and are designed to match the specific material properties of the product.

Depending on the application, blade shape and configuration vary to ensure clean separation and consistent portion sizes.

Technical Data:

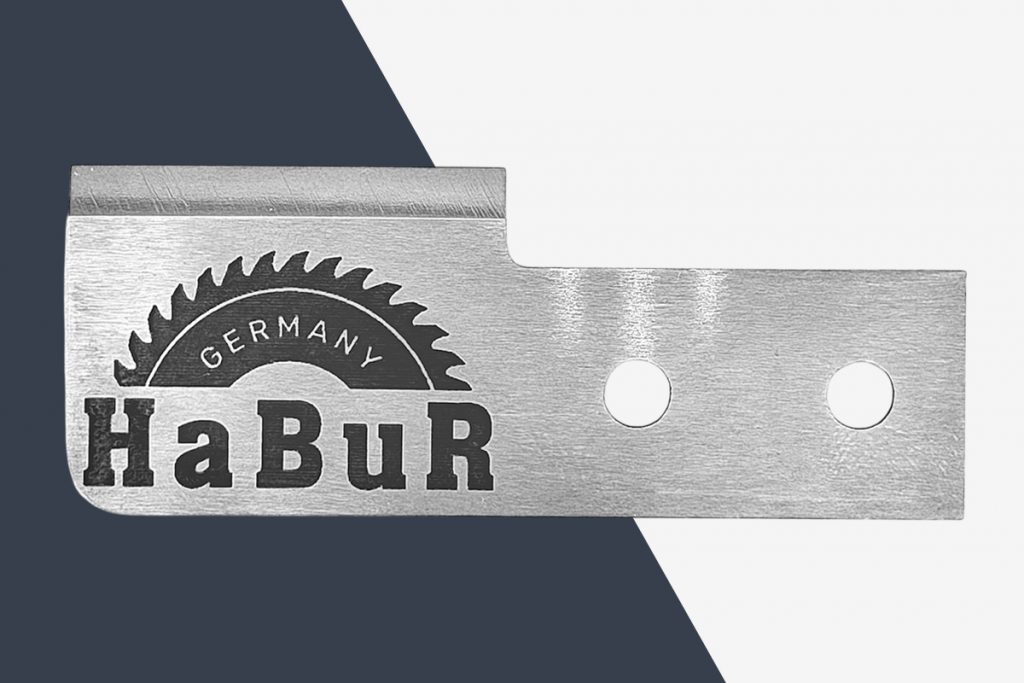

Candy cutting knife for confectionery mass

Material: according to specification

Dimensions: variable

Cutting geometry: adapted to product and process requirements

Surface finish: uncoated or coated upon request

Technical Data:

Curved cutting knife for sugar mass

Material: according to specification

Dimensions: variable

Cutting geometry: adapted to product and process requirements

Surface finish: uncoated or coated upon request

The illustrations show typical configurations. Further knives for confectionery applications can be supplied upon request.

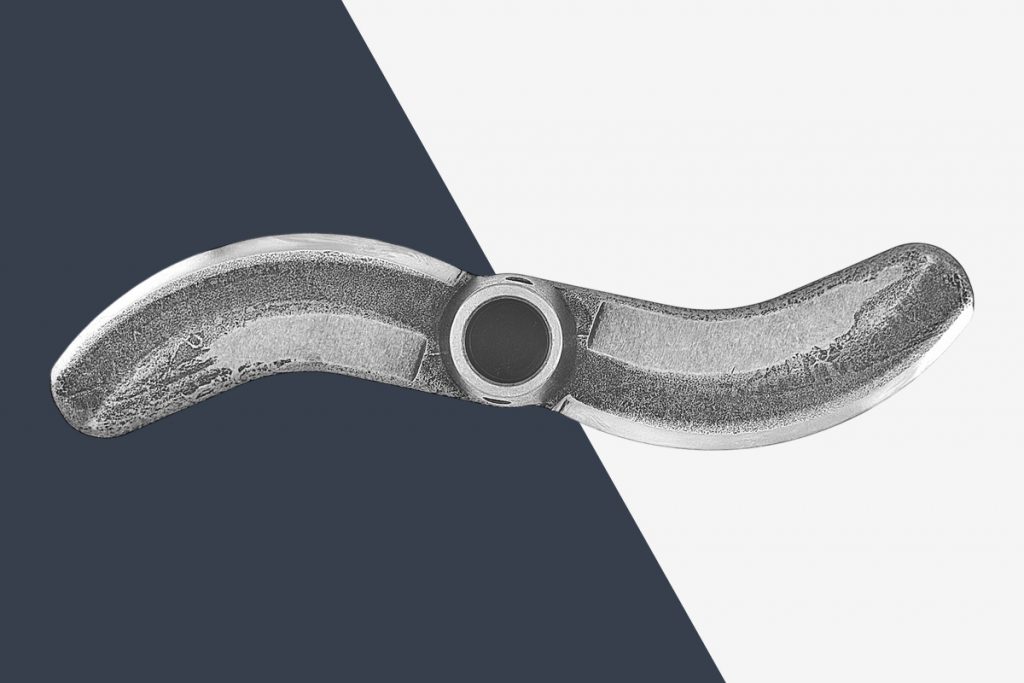

Blades for Industrial Mixers and Mixing Systems

These mixing blades are used in large-scale mixers to move, blend and evenly distribute materials during mixing and kneading processes. Shape and configuration are designed according to the specific mixer type and the properties of the processed material.

Technical Data:

Mixer wing blade for industrial mixing systems

Material: according to specification

Dimensions: variable

Cutting geometry: adapted to product and process requirements

Surface finish: uncoated or coated upon request

The illustrated blade represents one possible configuration. Further variants can be supplied upon request.

Plastic Processing

For the processing of plastics as well as films and tubular films, we supply knives and cutting tools for various separating and cutting applications. Our machine knives are used in extruders, granulation systems, winding machines, bag-making lines and packaging systems.

Depending on the material properties, the tools are designed for cutting or perforating operations. Blade configuration and cutting geometry are adapted to the material, the process and the specific equipment. Custom designs are available upon request.

Machine Knives for Film and Tubular Film Processing

These knives are used in the processing of films and tubular films, for example in the production of bag packaging with cutting or tear-off functions. Depending on the application, blade design and cutting geometry are adapted to the material and the specific process.

The examples shown represent typical configurations. We manufacture knives according to your required specifications. Submit your specifications to receive a tailored quotation.

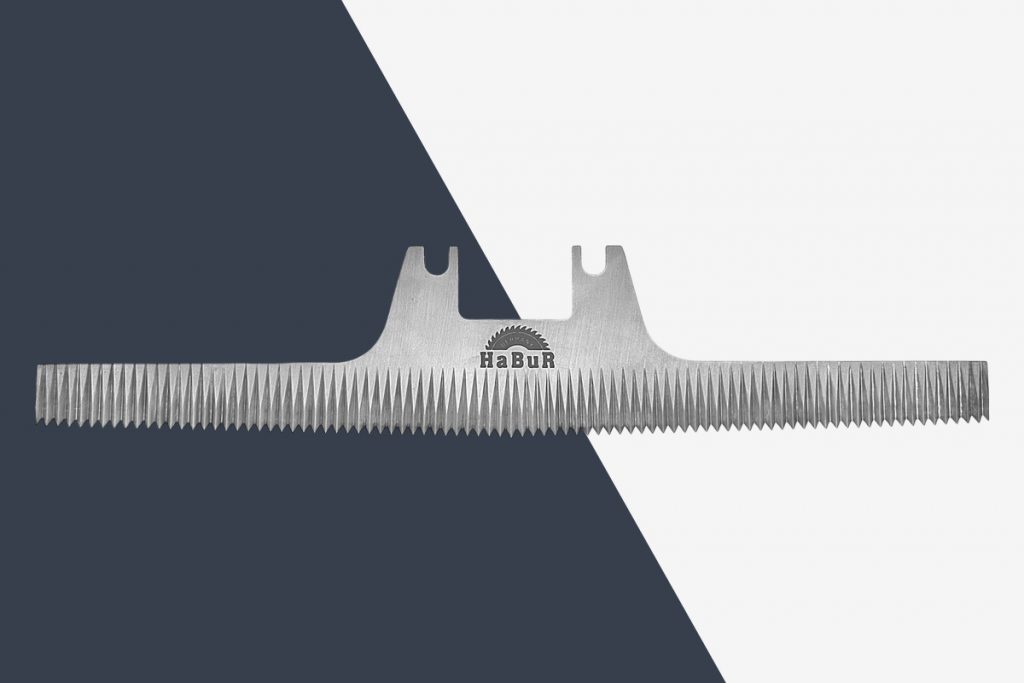

Technical Data:

Poly bag knife for tear-off bag packaging

Material: according to specification

Dimensions: variable

Cutting geometry: adapted to product and process requirements

Surface finish: uncoated or coated upon request

Technical Data:

Conical Poly bag knife for tear-off bag packaging

Material: according to specification

Dimensions: variable

Cutting geometry: adapted to product and process requirements

Surface finish: uncoated or coated upon request

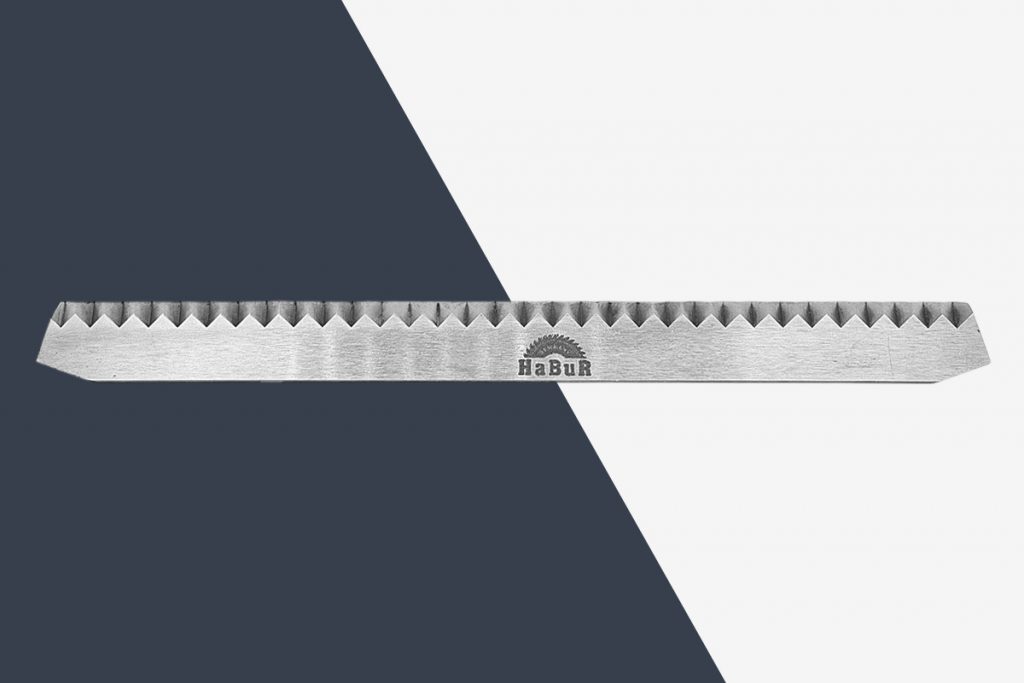

Technical Data:

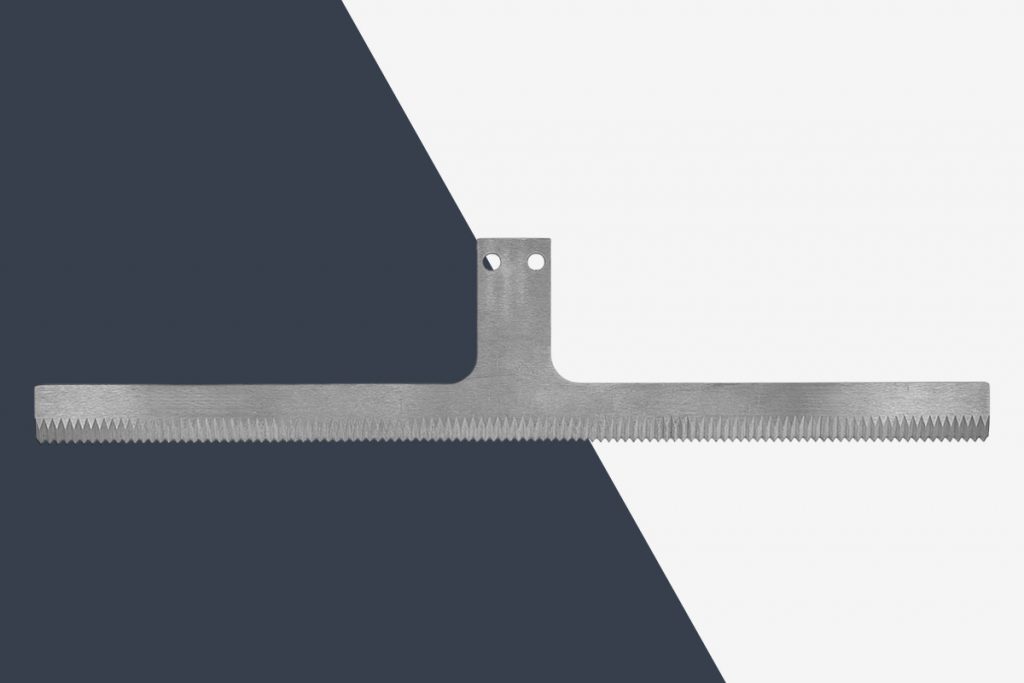

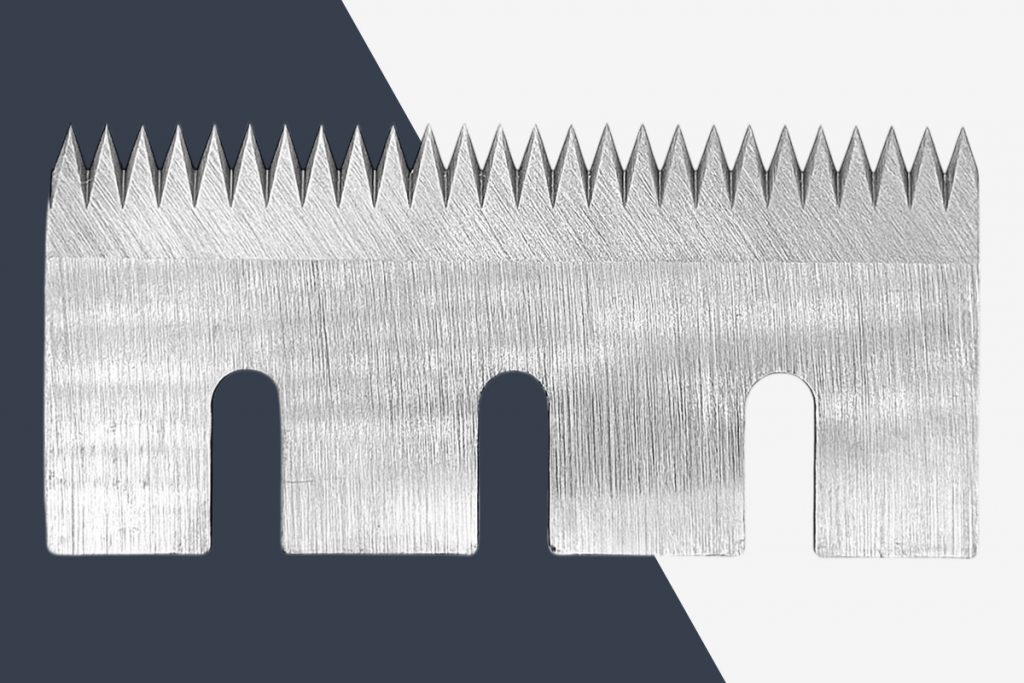

Long zigzag cutting knife for waste-free separation with tear-off function

Material: according to specification

Dimensions: variable

Cutting geometry: adapted to product and process requirements

Surface finish: uncoated or coated upon request

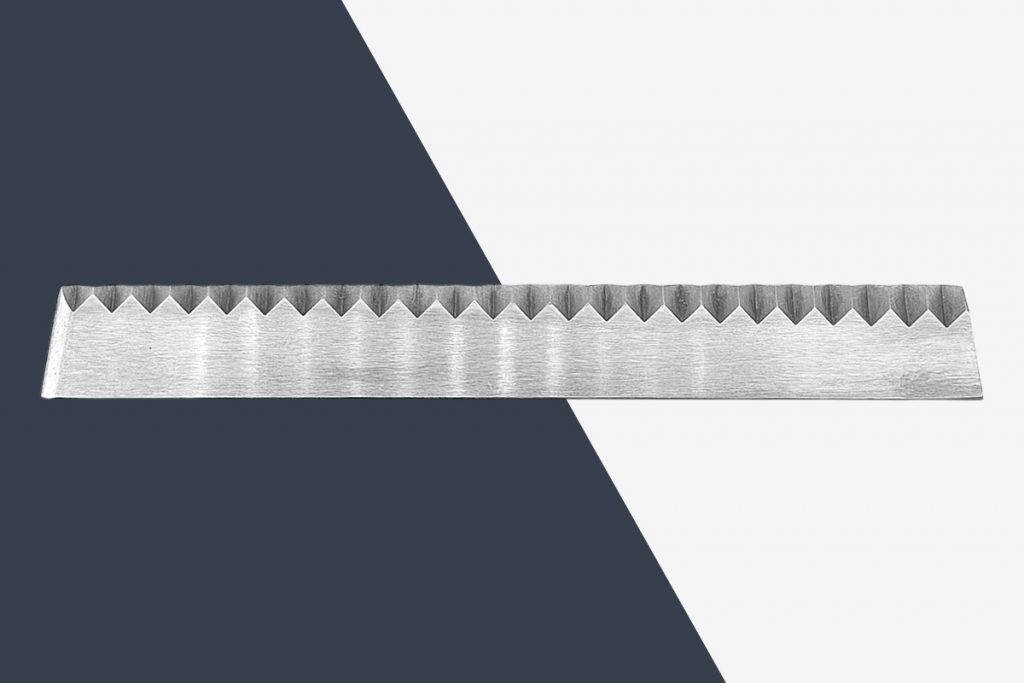

Technical Data:

Short zigzag cutting knife for waste-free separation with tear-off function

Material: according to specification

Dimensions: variable

Cutting geometry: adapted to product and process requirements

Surface finish: uncoated or coated upon request

Technical Data:

Angled zigzag cutting knife for waste-free separation with tear-off function

Material: according to specification

Dimensions: variable

Cutting geometry: adapted to product and process requirements

Surface finish: uncoated or coated upon request

Technical Data:

Perforating knife with fine serration for controlled tear-off systems

Material: according to specification

Dimensions: variable

Cutting geometry: Fine serration ensures precise perforation and consistent tear characteristics

Surface finish: uncoated or coated upon request

Technical Data:

Perforating knife with coarse serration for controlled tear-off systems

Material: according to specification

Dimensions: variable

Cutting geometry: Coarse serration ensures defined perforation and reliable tear characteristics

Surface finish: uncoated or coated upon request

Technical Data:

Perforating knife with coarse serration for controlled tear-off systems

Material: according to specification

Dimensions: variable

Cutting geometry: adapted to product and process requirements

Surface finish: uncoated or coated upon request

Technical Data:

Perforating knife with fine serration for controlled tear-off systems

Material: according to specification

Dimensions: variable

Cutting geometry: adapted to product and process requirements

Surface finish: uncoated or coated upon request

The illustrations show typical configurations. Additional knives for film and tubular film applications are available upon request.

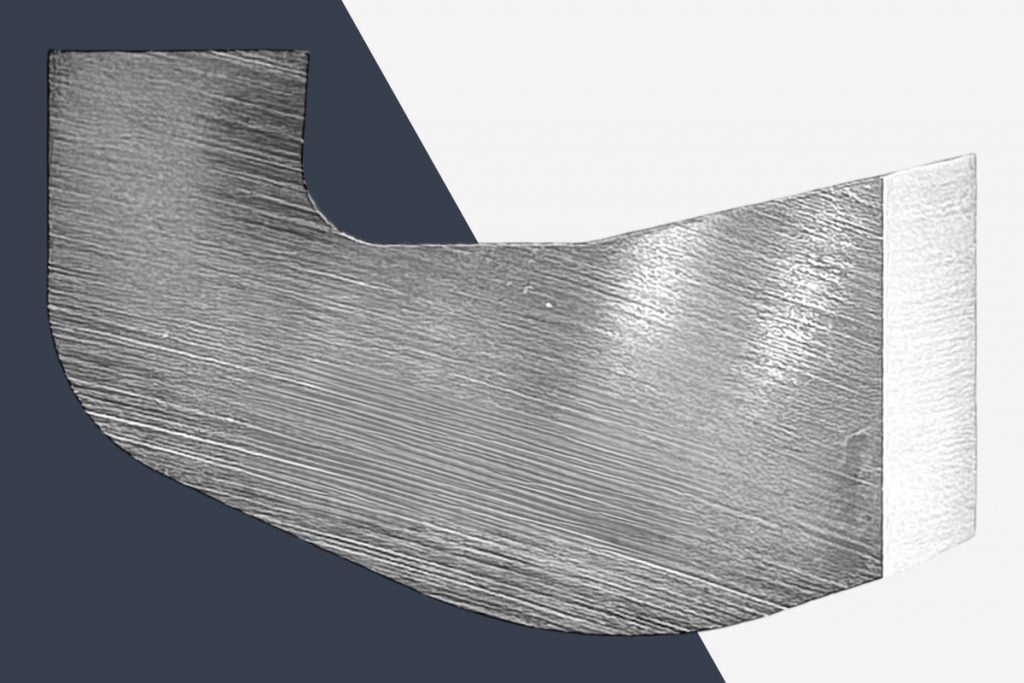

Machine Knives for Granulation and Size Reduction Systems

These knives are used in granulation and size reduction systems within plastic processing applications, including extruders and pelletizing systems. They cut the emerging plastic strand or reduce material during continuous operation. Depending on the equipment, straight or curved blades are used. The blade geometry is adapted to extruder, strand pelletizing or pelletizer systems and directly influences cut quality and tool life.

Technical Data:

Granulator knife with straight cutting edge

Material: according to specification

Dimensions: variable

Cutting geometry: adapted to product and process requirements

Surface finish: uncoated or coated upon request

Technical Data:

Curved granulator knife

Material: according to specification

Dimensions: variable

Cutting geometry: adapted to product and process requirements

Surface finish: uncoated or coated upon request

These examples represent typical granulator knife designs. Alternative geometries and custom configurations can be supplied upon request.

Machine Knives for Custom Applications

This section includes special knives and dedicated tools for specific applications within plastic processing, such as Big Bags, winding machines, packaging systems or bag closure mechanisms. Design and function are tailored to the respective process. Submit your technical drawing – we will review feasibility.

Technical Data:

Cut-off knife for winding machines and adhesive tape applications

Material: according to specification

Dimensions: variable

Cutting geometry: adapted to product and process requirements

Surface finish: uncoated or coated upon request

Technical Data:

Big Bag knife with triangular cutting geometry

Material: according to specification

Dimensions: variable

Cutting geometry: adapted to product and process requirements

Surface finish: uncoated or coated upon request

Technical Data:

Serrated knife for plastic packaging

Material: according to specification

Dimensions: variable

Cutting geometry: adapted to product and process requirements

Surface finish: uncoated or coated upon request

Technical Data:

Clip bending tool for bag closures

Material: according to specification

Dimensions: variable

Cutting geometry: adapted to product and process requirements

Surface finish: uncoated or coated upon request

Do you have a specific application or require a customized solution? Send us your inquiry.

Individual production & special solutions

In addition to our standard designs, we offer customized machine knives, precisely tailored to your application. Our production allows us to implement individual drawings, material requirements, edge shapes, or drilling patterns – whether as a one-off, prototype, or small series. We take special operating conditions such as high temperatures, aggressive media, or particularly hard materials into account. We also reliably implement special solutions with coatings, hardening treatments, or combinations of different cutting materials. Each product undergoes careful testing to ensure the highest dimensional accuracy, repeatability, and durability.

Quality you can rely on

Our machine knives are made from high-quality tool steels or special alloys. State-of-the-art grinding technology and strict quality controls ensure consistently high cutting performance, dimensional accuracy, and durability – even in demanding applications.

Personal advice & contact

Are you looking for a specific knife or need support in implementing your requirements? Our team is ready to assist you. Contact us – together we’ll find the right solution.

HaBuR Machine knives – quality that cuts.

Please feel free to contact us:

Machine knife

Share some key information with us so we can suggest the perfect product for you.

The more information you provide, the more suitable our solution will be.